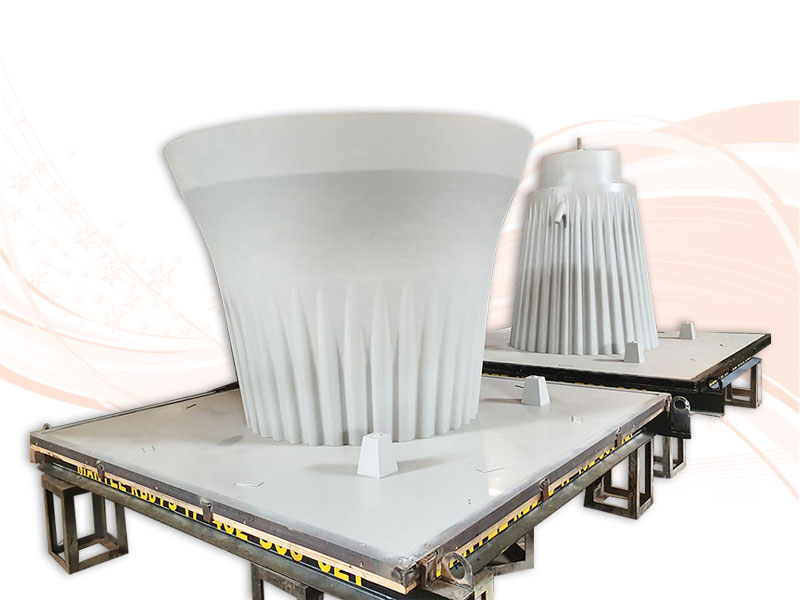

A cope and drag pattern is a split heavy having the cope and drag portions each mounted on separate match plates. These patterns are used when in the production of large castings; the complete molds are too heavy and unwieldy to be handled by a single worker.

View More

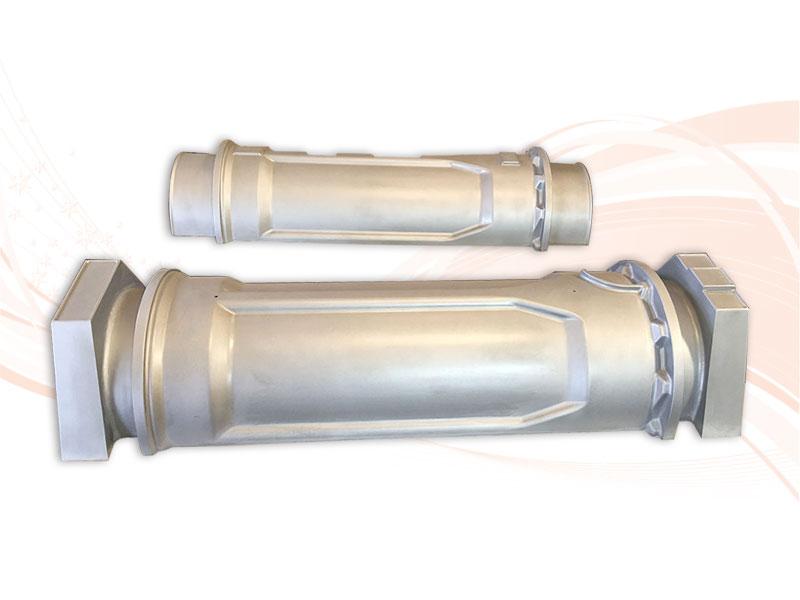

Wooden patterns are also named wooden molds, which are made in pattern workshops, the materials are wood.

View MoreThe offered products are ideal for use in various specialized casting and molding processes. Available with us at standard market prices, these products are high in demand in the market.

View More

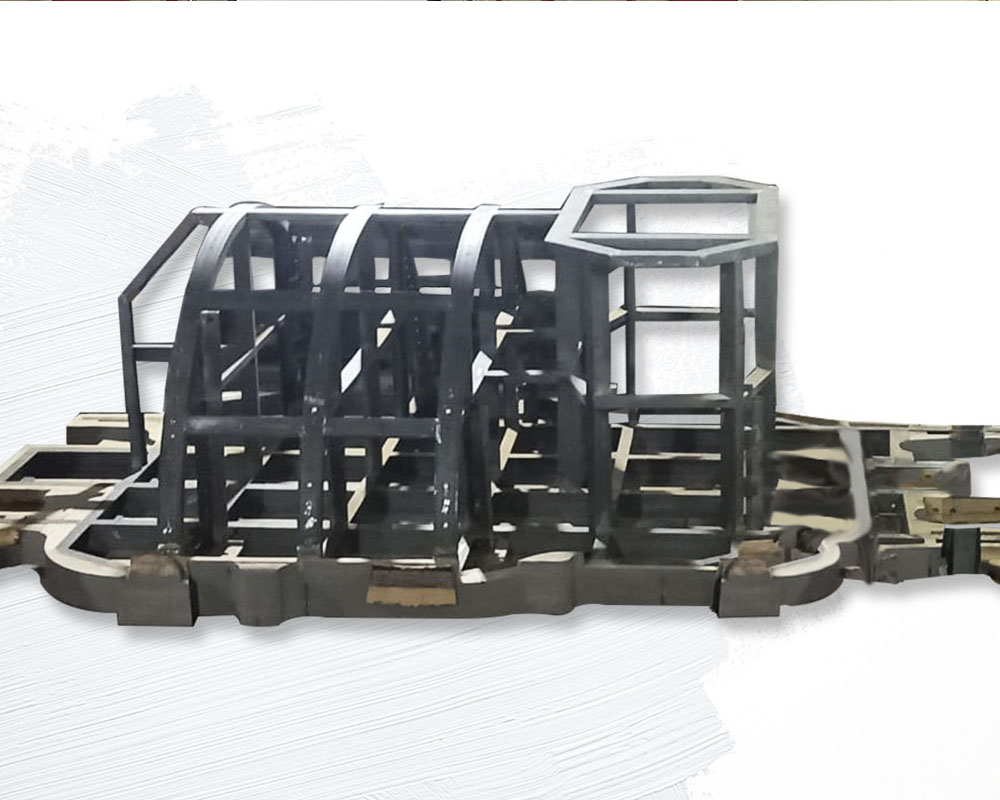

we present a concept for the fabrication of hydrophobic nanostructures on the cavities of microstructures of the mold, which can effectively decrease the ink residing on the cavities of the mold during coating.

View More